Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

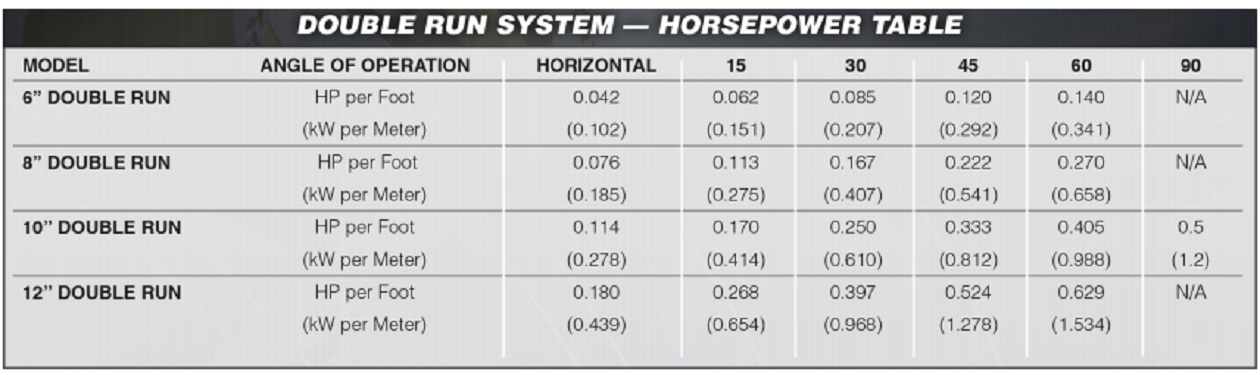

Low Power Requirements:

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted by Paul Boechler on Sep 14, 2020 in New Products

Tagged AGI, Hutchinson, Double Run, Chain Conveyor, Grain Handling, Grain Systems, Flaman