From start to finish, the Flaman Grain Systems team is right beside you

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish. ...

Posted by Mitch Flaman on Apr 7, 2021 in Division News

Tagged Grain Systems, Grain Handling, Grain Drying, Grain Cleaning, Optimization, Site Drawings, Yard Planning

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

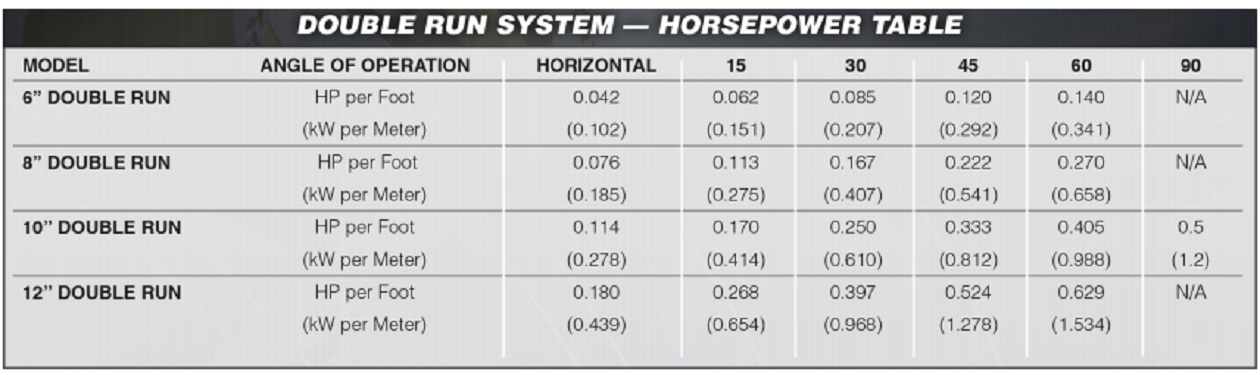

Low Power Requirements:

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted by Paul Boechler on Sep 14, 2020 in New Products

Tagged AGI, Hutchinson, Double Run, Chain Conveyor, Grain Handling, Grain Systems, Flaman

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site....

Posted by Calla Simpson on Aug 31, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Walinga, Ultra-Veyor, Blower System, NECO, Grain Dryer

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying....

Posted by Calla Simpson on Aug 26, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Grain Drying, NECO, Grain Dryer, Mixed Flow, Continuous Flow

Dry your grain with ease: Get ahead of harvest this year and book your NECO dryer install with Flaman today

NECO Mixed Flow Grain Dryers are designed to easily and efficiently condition all types of grain for storage. With no screens to clean or unplug, this industry-leading grain dryer is designed not only for its performance, but also its versatility.

The flexible, modular design of these grain dryers make for easy installation and can be customized and expanded to suit any farming operation.

A time lapse of a NECO Grain Dryer installation near Saskatoon

The NECO Grain Dryer’s mixed flow operation ensures even heating and cooling to provide consistent, high-quality grain. The improved air flow, quieter fans, and unequalled fuel efficiency make this dryer a valuable addition to any farming operation.

NECO dryers use Commander Control with a Dryer Master moisture control system to protect the quality of your grain and prevent over- or under-drying. The COMMANDnet system allows remote access to your NECO Grain Dryer to monitor its performance from your smartphone or computer – providing you with total control over your dryer wherever you may be.

It is never too early to start planning for harvest, as we never know what mother nature has in store for us. Bookings are filling up fast, but there are still a few spots left to get your name on a dryer for fall. Our Grain Systems team can customize a complete grain drying system to suit your needs, guiding the setup and installation, and providing service and maintenance along the way.

Hear first-hand from Flaman customers what a NECO dryer can do for your operation

Be ready to get ahead of harvest this year – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted by Calla Simpson on Jun 26, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Grain Drying, NECO, Grain Dryer

Be ready for harvest 2020: Summer is the time to build your bins & install your grain handling equipment

As seeding is coming to a close throughout the province, you may be starting to think about the next steps in your farming operation for 2020. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long....

Posted by Calla Simpson on May 29, 2020 in Ag news

Tagged Grain Systems, Grain Handling, Grain Drying, Grain Cleaning, Turnkey, Bin Site, NECO, Walinga

Harvest 2019: An unconventional way to dry your grain in wet conditions

The 2019 harvest is shaping up to be frustrating for most. It’s no secret that harvest is well behind this year, with only 34% of crops being combined in Alberta (47% 3-yr avg), 47% in Saskatchewan (75% 3-yr avg), and 71% in Manitoba (85% 3-yr avg) as of last week. Wet weather has plagued the prairies, with record rainfall in Manitoba and snowfall in southern Alberta & Saskatchewan in September. A combination of high moisture levels and widespread crop damage has contributed to diminished grade.

It’s now a race to get remaining crops off the field and although we can’t control the weather, we can help you maintain the grade of your grain by getting it dried faster and limiting spoilage. The most effective option is a NECO dryer from Flaman, which can be scaled to the size of your operation. However, dryer installs are contingent on many environmental and logistical factors and it’s far from a guarantee that a dryer purchased today would be installed before the end of harvest.

So, what does a farmer do if he or she can’t get a dryer installed in time?

Our team in Saskatchewan has heard a lot of stories from our customers who’ve resorted to unconventional methods to dry their grain. The overwhelming favourite by local farmers has been the Frost Fighter (available only at our Saskatchewan locations), which is a diesel-powered 350,000 BTU industrial heater designed to heat remote construction sites and shops. As it turns out, they are also easily adaptable to a bin aeration system and can pump heat into two bins simultaneously. It’s been a lifeline given the soggy conditions.

Kelly Stewart, the operations manager at our Flaman Moosomin location, was the man who made this idea a reality:

“I saw a video a couple years ago of an Alberta farmer using a similar method and he claimed it worked like a charm. It inspired me to try it out given how wet it’s been this year. Some local farmers put it to work and were extremely pleased with the results. It’s not a perfect solution and we know it’s not recommended by the manufacturers, but desperate times have forced us to think outside the box.

With a little extra work, moving your grain around and monitoring your moisture levels closely, we’ve heard from many happy customers that have seen up to 30,000 BU dried in a week. Obviously, the best way to dry your grain is with a dryer but given how wet it’s been and with more precipitation in the forecast, this has been a great makeshift way to salvage what has been a tough harvest.”

Interested in learning more about grain drying? Talk to one of our agriculture specialists at your nearest Flaman location.

Posted by Paul Boechler on Oct 9, 2019 in Ag news

Tagged Grain Drying, Frost Fighter, Neco Dryer, Flaman, Harvest, Crops, Aeration

The secret behind cleaning grain with indent cylinder machines

The indent cylinder machine is designed primarily to separate grain by kernel length. It separates long kernels from shorter ones. The cylinder itself is a thin-walled tube with indents formed on the inside to the shape of a hemisphere. These indents are known as pockets....

Posted by Roy Ritchie on Aug 22, 2012 in Product Information

Tagged Grain Cleaning, Indent Cylinder, Grain Kernel, Flaman, Grain Sorting

Operation of a Air Screen Grain Cleaner

Operation of an Air and Screen

As the name implies, air screen machines use a combination of suction air that is drawn through the curtain of grain as it falls from the hopper onto a series of screens. The screens then size the product by width of the kernel, and a final air suction process is used....

Posted by Roy Ritchie on Jan 27, 2012 in Product Information

Tagged Grain Cleaning And Handling, Air Screen Grain Cleaner, Sieve, Sift, Scalf

What is Ergot?

Ergot is a type of fungus that grows on many grasses, rye, wheat, barley, and triticale.It infects the floret of the grass or cereal and mimics the process of pollinated grain growing on the plant. On ergot infected plants, a spore destroys the ovary, and then connects to the plant by attaching itself to the plant’s seed nutrition system. An infected floret can also infect other florets by insect dispersal of the asexual spores. That means that an insect can carry millions of the spores to other plants in the region. When mature ergot drops to the ground the fungus remains dormant until proper conditions trigger its fruiting phase, germinate and re-infest an area....

Posted by Roy Ritchie on Dec 12, 2011 in Product Information