Flaman Launches First Storefront Location in Peace River Region

...

...

Posted by Jeff Brown on Oct 27, 2021 in Local News

Tagged Flaman, Fairview, Peace Country, Alberta, Sales, Rentals

Increase efficiency & reduce downtime during spraying this year

Model ST-9100...

Posted by Mitch Flaman on Mar 5, 2021 in New Products

Tagged Spraying, Sprayer Trailer, Ag Trailer, Flaman, ST-9100, ST-9200

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

Low Power Requirements:

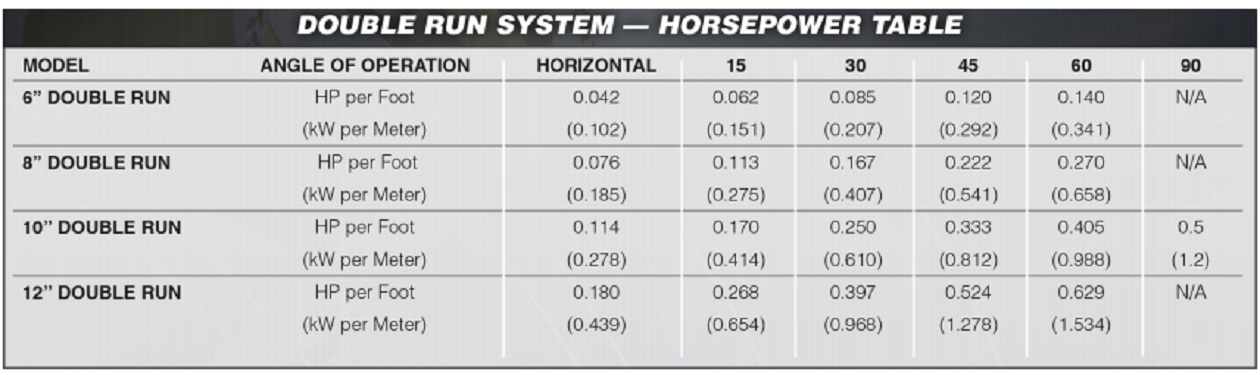

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted by Paul Boechler on Sep 14, 2020 in New Products

Tagged AGI, Hutchinson, Double Run, Chain Conveyor, Grain Handling, Grain Systems, Flaman

A Brief History of the Newest Flaman Store in Swift Current

The Flaman Swift Current and Gatco location

Products Designed by a Farmer, For Farmers

Gatco was started by a Saskatoon area farmer, Gary Schreiner. Schreiner had a problem: he was losing canola bins to overheating and needed a solution for remote bin yards that had no power. He began trying different combinations of perforated tubes in an effort to create a venting system inside the grain bin. This led to the creation of the GrainAir Tube powerless aeration system. The GrainAir tube allows heat and moisture to escape the bin quickly, by letting heat collect in the central tube and relying on convection to remove heat from the bin without any fans.

A couple year’s later, Schreiner was moving his load out auger and plastic hopper in his yard and slipped while maneuvering the plastic hopper. He knew there had to be a safer way to do this, and so the Auger Hog Hopper was born. This adjustable, detachable grain auger hopper attaches and detaches in seconds with a single mount pin, stays on your auger between bins, and adjusts from 12" to 29" in height merely by moving the handle. Due to the Auger Hog’s u-trough design, it also increases the average augers speed by 20-25% and prevents any product loss.

The Auger Hog

With the GrainAir tube working well, Schreiner felt there had to be a way to make a more efficient aeration system. While researching grain dryers, he found that air moved through grain easier horizontally, so he developed louvered wall columns that were pressurized with a common aeration fan. The air would leave the wall columns and travel horizontally to the central GrainAir tube and be released out through the bin lid quickly and easily. This CrossFlow system is far more efficient than traditional air systems, as the air travels less distance and moisture and heat is removed from the bin much faster.

“Gary came up with these unique solutions to help make farming easier,” says Bret Watson, Gatco division manager, who’s worked for the company since 2013.

Bret Watson (Gatco Division Manager & Flaman Operations Manager)

Bret Watson (Gatco Division Manager & Flaman Operations Manager)A Natural Partnership in Swift Current

It was that line of innovative, farmer-proven products that made Gatco a natural fit to join the Flaman team, says Watson, who is also the operations manager for Flaman’s Swift Current location. Gatco was purchased by Flaman Sales in 2018, when Schreiner decided he wanted to devote more time to his farming operation. “The companies are both family-owned and started on the farm,” says Watson. “We were selling to the same customers and trying to provide that same level of service. It was a nice, natural fit.”

With that purchase, Flaman Sales started their 7th store in Saskatchewan. The Swift Current location began as one-person business with Watson, but since February 2020 has added 5 more staff in sales, administration and yard staff, along with acquiring a second, 4-acre yard to expand on-hand inventory and provide better sales and service.

Mellissa Paxman (Administration), Bruce Deg (Ag Sales), Brittany Fiddler (Logistics Coordinator), and Rick Spanier (Yard & Support)

The Swift Current store is a full-service Flaman Agriculture equipment dealership, offering a wide range of in-stock grain-handling equipment such as augers, conveyors, post pounders, grain vacs, grain carts, grain bins, grain dryers, grain monitoring, and water and fertilizer tanks. Customers can also order products from the Flaman catalogue like discs, mowers, chem handlers, pumps, and more.

Bob Schafer (Ag Sales)

Bob Schafer (Ag Sales)“We’re proud to offer equipment options to the local community,” says Watson. “Farmers don’t have to drive to Saskatoon or Southey anymore. This location allows Flaman to serve customers all over southwest Saskatchewan.”

-----

Want to learn more? You can view some products in inventory or contact our Swift Current location.

Posted by Jennifer Thompson on Jul 7, 2020 in Division News

Tagged Agriculture, Swift Current, Flaman, New Store, Local, Shop Local, Southwest Saskatchewan

Harvest 2019: An unconventional way to dry your grain in wet conditions

The 2019 harvest is shaping up to be frustrating for most. It’s no secret that harvest is well behind this year, with only 34% of crops being combined in Alberta (47% 3-yr avg), 47% in Saskatchewan (75% 3-yr avg), and 71% in Manitoba (85% 3-yr avg) as of last week. Wet weather has plagued the prairies, with record rainfall in Manitoba and snowfall in southern Alberta & Saskatchewan in September. A combination of high moisture levels and widespread crop damage has contributed to diminished grade.

It’s now a race to get remaining crops off the field and although we can’t control the weather, we can help you maintain the grade of your grain by getting it dried faster and limiting spoilage. The most effective option is a NECO dryer from Flaman, which can be scaled to the size of your operation. However, dryer installs are contingent on many environmental and logistical factors and it’s far from a guarantee that a dryer purchased today would be installed before the end of harvest.

So, what does a farmer do if he or she can’t get a dryer installed in time?

Our team in Saskatchewan has heard a lot of stories from our customers who’ve resorted to unconventional methods to dry their grain. The overwhelming favourite by local farmers has been the Frost Fighter (available only at our Saskatchewan locations), which is a diesel-powered 350,000 BTU industrial heater designed to heat remote construction sites and shops. As it turns out, they are also easily adaptable to a bin aeration system and can pump heat into two bins simultaneously. It’s been a lifeline given the soggy conditions.

Kelly Stewart, the operations manager at our Flaman Moosomin location, was the man who made this idea a reality:

“I saw a video a couple years ago of an Alberta farmer using a similar method and he claimed it worked like a charm. It inspired me to try it out given how wet it’s been this year. Some local farmers put it to work and were extremely pleased with the results. It’s not a perfect solution and we know it’s not recommended by the manufacturers, but desperate times have forced us to think outside the box.

With a little extra work, moving your grain around and monitoring your moisture levels closely, we’ve heard from many happy customers that have seen up to 30,000 BU dried in a week. Obviously, the best way to dry your grain is with a dryer but given how wet it’s been and with more precipitation in the forecast, this has been a great makeshift way to salvage what has been a tough harvest.”

Interested in learning more about grain drying? Talk to one of our agriculture specialists at your nearest Flaman location.

Posted by Paul Boechler on Oct 9, 2019 in Ag news

Tagged Grain Drying, Frost Fighter, Neco Dryer, Flaman, Harvest, Crops, Aeration

NECO Grain Dryer Build

.jpg)

We had help from several outside sources: Freeway Transport, who were responsible for the dryer delivery; Xcaliber Crane & Rigging who handled the hoisting of the dryer; and Continental Bins, who provided assembly services. Additionally, Ron Kleuskens from NECO supervised the build and many members of the Flaman Nisku team assisted throughout the day where they were needed. And most importantly, the 4 owners of the farm and their sons, daughters, grandchildren & significant others were all present at one time or another throughout the day. They were the real supervisors!

.jpg)

Build Day was kicked off with the delivery of the dryer. This consisted of 7 truckloads originating in Omaha, Nebraska. Each delivery was staggered by 2 hours, which allowed enough time for our crane and assembly teams to position and install each section before the next was delivered.

.jpg)

With the help of our partners and employees – more than 20 people in total -- we were able to install this behemoth of a dryer in one jampacked, 10 hour day.

.jpg)

The dryer will serve as a flagship operation in the area and will likely create business not only for our customer’s farm, but others in the area as well. It’ll be an economic driver in the area for many years to come. We're thankful to be a part of this project and meet the needs of our customer. Customer service is one of the core beliefs Flaman was founded on and it’s why we’re celebrating 60 years in the agriculture industry in Western Canada.

Posted by Paul Boechler on Jun 12, 2019 in Ag news

Tagged Grain Dryer, Farming, Neco, Flaman, Install

Disney's Approach To Quality Service

Flaman Welcomes Disney Institute to Saskatoon.

We aspire in the betterment of your staff, and our customers...

Posted by Steve Whittington on Nov 18, 2016 in Local News

Tagged Disney, Institute, Customer Service, Seminar, TCU, Flaman, Saskatoon

10th Annual Frank J. Flaman Foundation Gala 2016

The location is new – it will be at the Fantasyland Hotel - and the theme is “The Roaring Twenties!” There will be prizes for best costumes and the evening is sure to be an extraordinary and unforgettable one.

Frank Flaman funds the administration and overhead costs of the Foundation, so 100% of every dollar donated goes to a charity, event, or someone in need. To date, over $10-million has been donated to various charities.

The Frank J. Flaman Foundation’s and Frank’s mission to help those that need assistance in our community, our country, and around the world. The Foundation will focus more on the needs of children and families locally in 2016.

Read more about "Why Frank Cares" here.

The goal is to raise $80,000 at the Gala, with the funds, in addition to the hundreds of thousands of dollars that the Frank J. Flaman Foundation gives each year, being pledged to various charities including the ones mentioned here [https://www.flaman.com/foundation/charities ]. Through these joint partnerships, the Foundation hopes to improve the quality of life for all in need and help to end world suffering.

The Frank J. Flaman Foundation’s “Gala” is the annual main fundraiser for the Foundation. During this elegant and fun evening, a silent auction takes place as well as dinner and dancing. But this event is not just about raising money, it’s also about showing attendees and supporters how their contributions are making a difference. Representatives from a number of charities are on hand to receive their donations from Frank himself. As well, charitable groups are showcased for everyone to learn about the great work that they do.

Why does Frank want to make a difference in the world? Frank has spent many years learning, reading and researching opportunities in the world and how he can help to end global suffering. He has discovered two major things:

- The lack of unsafe water and sanitation are the world’s largest causes of illness.

- Food security is of utmost importance! Lack of sustainable food sources leads to malnutrition and death in most parts of the world.

So, for over 30 years, Frank has personally funded and helped countless charities, both locally and around the globe. In 2005, he formally established the Frank J. Flaman Foundation to expand these philanthropic efforts. In the first two years alone, he brought aid to thousands worldwide and every year following the foundation continues to spread the generosity of Frank and other donors to those in need.

The Frank J. Flaman Foundation is funded by Frank’s share of the profits from the Flaman Group of Companies, as well as private donations from others.

The cost per ticket is $150 and per table of 10 is $1350.

Also, you can support the event with your donation of silent and live auction items. “One of a kind” or unique items bring in the most money in an auction. Examples of items that have been very popular at auctions include sports memorabilia, artwork, gift certificates and rare or different collectibles. For any item you donate, you will receive a charitable receipt in the amount of the full retail value of the item along with recognition at the event!

Contact is Syndy Harriott @ 780-955-3402 or email her at syndy.harriott@flaman.com

For hotel reservations, please contact the Fantasyland Hotel (780-444-3000 or 1-800-737-3783). Ask for the Frank J. Flaman Foundation Dinner or Frank J. Flaman Foundation Gala. The pricing is $175/night/room. There is a room block set aside at this special price. Their address is 17700 – 87 Ave NW. Edmonton, AB. T5T 4V4.

Posted by on Feb 8, 2016 in Local News

Tagged Frank Flaman Foundation

Why Frank Cares

- The lack of unsafe water and sanitation are the world’s largest causes of illness.

- Food security is of utmost importance! Lack of sustainable food sources leads to malnutrition and death in most parts of the world.

So, for over 30 years, Frank has personally funded and helped countless charities, both locally and around the globe. In 2005, he formally established the Frank J. Flaman Foundation to expand these philanthropic efforts. In the first two years alone, he brought aid to thousands worldwide and every year following the foundation continues to spread the generosity of Frank and other donors to those in need.

The Frank J. Flaman Foundation is funded by Frank’s share of the profits from the Flaman Group of Companies, as well as private donations from others.

Frank funds the administration and overhead costs of the Foundation, so 100% of every dollar donated goes to a charity, event, or someone in need. To date, over $10-million has been donated to various charities.

The number of organizations that have received support from the Foundation is includes both local and global charities. Frank believes that every one of us can make a difference and that a needy person is a needy person, whether they live just down the street or thousands of miles away. The Foundation will focus more on the needs of children and families locally in 2016.

Charities supported by the foundation include:

- Crystal Kids (mentoring children and teens in the urban Edmonton area)

- E4C Snack Program (offering school lunch programs in Edmonton inner-city schools)

- Kid’s Kottage (promoting the health and wellbeing of children and their families and helping end child abuse and neglect)

- Lurana Shelter (meeting the needs of women and children fleeing from domestic violence)

- Mennonite Central Committee (the foundation assists MCC in their quest to ensure sustainable food sources, adequate housing, education and independent living),

- Mother Teresa Missionaries of Charity (serving the “poorest of the poor” with more than 500 missions in over 100 countries)

- Operation Eye Sight (with Frank’s donations over 5,000 individuals in the developing world have had their eyesight restored)

- Oxfam (tackling the root causes of poverty and inequity, and helping people to create self-reliant and sustainable communities)

- Partners in Health (saving lives, revitalizing communities & transforming global health)

- Pilgrims Hospices Lottery (Edmonton’s only free-standing voluntary Hospice)

- Room to Read (transforming the lives of millions of children around the world by focusing on literacy and gender equality)

- The Salvation Army (largest non-governmental direct provider of social services in Canada)

- Effect Hope (healing the physical, emotional and spiritual needs of people affected by leprosy living in the poorest areas)

- Water Ambassadors Canada (changing lives with clean water)

- YESS - Youth Emergency Services Shelter (empowering youth from difficult realities)

- WIN House (Edmonton Women’s Shelter Ltd)

- ADF - Alberta Diabetes Foundation (Funding life changing diabetes research in Alberta)

- Change for Children (the Foundation assists Change for Children in promoting action for systemic change and sustainable development. It aims to support the poor in securing their own food sources, safe water and political autonomy.)

- Catholic Social Services (offering over 100 programs to all faiths and cultures in central and north east Alberta)

The Frank J. Flaman Foundation also takes volunteers, staff members from the Flaman Group of Companies, and others interested, on mission trips around the world including to Guatemala, Honduras, and Nicaragua. You can see the trip photo albums here. At these locations, teams work to build schools, medical facilities, and water infrastructure.

The Frank J. Flaman Foundation’s “Gala” is the annual main fundraiser for the Foundation. During this elegant and fun evening, a silent auction takes place as well as dinner and dancing. But this event is not just about raising money, it’s also about showing attendees and supporters how their contributions are making a difference. Representatives from a number of charities are on hand to receive their donations from Frank himself. As well, charitable groups are showcased for everyone to learn about the great work that they do.

This year’s gala is March 18th at Edmonton’s Fantasyland Hotel; the theme is “The Roaring Twenties” - there will be prizes for best costumes and the evening is sure to be an extraordinary and unforgettable one. The goal is to raise $80,000 at the Gala, with the funds, in addition to the hundreds of thousands of dollars that the Frank J. Flaman Foundation gives each year, being pledged to various charities including the ones mentioned above. Through these joint partnerships, the Foundation hopes to improve the quality of life for all in need and help to end world suffering.

For ticket sales or more information, please contact Syndy at 780-955-3400 or see https://www.flaman.com/foundation/events/

Posted by on Feb 8, 2016 in Local News

Tagged Frank Flaman Foundation

Flaman Fitness wins Edmonton Journal Readers Choice Award

“Today’s the Day.” Those three words have been dominant at Flaman Fitness in the past year. But for the national fitness company, they are not just a slogan, but a powerful message that Flaman wants to spread to all Canadians.

“It’s a message of hope that you can start your fitness journey any day,” says Steve Whittington, Flaman Fitness’ vice-president of marketing. “You don’t have to wait for a Monday or New Year’s Day. You just need to start. And it doesn’t have to be this grand gesture of a diet or a detailed workout plan. Just be a little more active each day and eat smarter. And we’re here to help you with that journey.”

The company launched the “Today’s the Day” campaign in October of last year and Whittington says customers have responded positively. A large proof of their success is the engagement that customers are having with the resources Flaman provides to help them. More people are coming to their website and reading their fitness blog.

But Whittington says customers can now look forward to a new, mobile-friendly website they’re launching shortly. A new section, called Learn, is loaded with fitness resources, including articles, workouts, videos and much more.

“Learn is for anyone, whether you’re a fitness enthusiast or just starting out,” says Whittington. “You can go here to get inspired and get great information on setting goals and improving your personal health.

“People are interested in the support we’re providing,” he adds. “We feel that this new site is o ering much more support for the customer and we hope it will resonate with them.”

Whittington believes that being selected for a Reader’s Choice Award in Edmonton again this year is reinforcement of the path the company is on to serve the customer first. And they want their message to reach beyond just their current customers.

“We have a health crisis in Canada,” says Whittington. According to 2014 statistics from Health Canada, 54 per cent of adults in the country and 23.1 per cent of youth in Canada are overweight or obese.

“As a national fitness brand with the reach that we have, I believe we have an obligation to join the fight to make Canada a healthier place.

“Maybe you didn’t run yesterday, but today’s the day you can!” says Whittington. “Every day can be a day that you can start. Fitness shouldn’t be solely about image, it’s about feeling better and living better.”

Here's how the page looked:

Posted by Flaman Agriculture on Nov 30, 2015 in Local News

Tagged Edmonton Journal, Readers Choice, Flaman Fitness

Interview with Flaman Nisku's Shop Foreman, Jeff Luciow

...

Posted by Flaman on Jun 3, 2015 in Local News

Tagged Shop, Foreman, Flaman, Nisku, Cooperation, Team, Leader

Flaman Yard Safety

Safety is everyone’s responsibility!...

Posted by Flaman on May 27, 2015 in Local News

Frank Flaman Foundation 9th Annual Gala

Myself, as well as all that I have spoken with who attended, agree that it was an amazing evening and we can’t wait for next year’s event. ...

Posted by Charlene Swanton on Apr 6, 2015 in Testimonials

Tagged Gala, Frank Flaman, Flaman Foundation

What is the NATM?

So if you’re looking for a new or used trailer, keep this in mind. Look for NATM dealer associate marked trailers and do your research. It’s worth it. ...

Posted by Flaman on Feb 23, 2015 in Trailer Tips

Nisku's Own JP Blenke Featured in Edmonton Journal

I am fortunate to get to work with an amazing group of people here at the Flaman Nisku store. We are all kind of like one big, crazy, supportive family. It makes coming to work everyday enjoyable because I know that at some point today I will get the chance to talk to one of my co-workers and learn something from them or share a laugh....

Posted by Flaman on Feb 10, 2015 in Local News

Tagged JP, Flaman, Edmonton Journal, Article, Triumph, Accident

2014 Flaman Rental Meeting in VEGAS!

...

Posted by Flaman on Dec 10, 2014 in Division News

Flaman Dragon Slayers Rip Up the River!

...

Posted by Flaman on Aug 22, 2014 in Local News

Tagged Dragon Boating, Flaman Dragon Slayers, Edmonton Dragon Boating Festival, 2014, Rip Up The River, Paddling

Reflecting Back on the April 2014 Frank Flaman Foundation Guatemala Humanitarian Trip

This blog was written with input from Brian Rask, Dave Schultz, Wayne Sumners and Barney Bartley all from our Prince Albert, SK location....

Posted by Flaman on Jun 11, 2014 in Local News

Tagged Frank Flaman Foundation, Reflecting, Guatemala, Humanitarian Trip

B & B Podcast

Jim Behnke from Behnke Enterprises talks to Steve about Ag Transports and changes he has seen in his 27 year career in the Trailer Industry. Behnke Enterprises is a truly world class and worldwide brand with distribution in many countries and continents. Behnke Enterprises manufacturers a diverse product line of Ag Transport equipment and industrial trailers that allows evolving. Listen, learn, and enjoy the podcast....

Jim Behnke from Behnke Enterprises talks to Steve about Ag Transports and changes he has seen in his 27 year career in the Trailer Industry. Behnke Enterprises is a truly world class and worldwide brand with distribution in many countries and continents. Behnke Enterprises manufacturers a diverse product line of Ag Transport equipment and industrial trailers that allows evolving. Listen, learn, and enjoy the podcast....

Posted by Steve Whittington on Jun 3, 2014 in Podcasts

Tagged Podcast, Flaman Trailers, Steve Whittington, Behnke Enterprises, Ag Transport, Industrial Trailers

Seed of Hope

Posted by Lorna Mutch on May 21, 2014 in Local News

Tagged Guatemala, Flaman Foundation, Experience, Hope

Southland New Products 2014 Podcast

In this Episode we talk with Ryan Sailer General Manager of Southland Trailers. Ryan takes us through three exciting new products from Southland Trailers. The E270 Dump Trailer, the SL 280 Dump Trailer and their Fuel pup trailer. Enjoy the conversation....

In this Episode we talk with Ryan Sailer General Manager of Southland Trailers. Ryan takes us through three exciting new products from Southland Trailers. The E270 Dump Trailer, the SL 280 Dump Trailer and their Fuel pup trailer. Enjoy the conversation....

Posted by Steve Whittington on May 6, 2014 in Podcasts

Tagged Podcast, Southland Trailers, Steve Whittington, Ryan Sailer, Flaman, Flaman Trailers

Bull Dog Truck Deck Podcast

In this episode of Trailer Talk we talk with Brett McDowell who shares with us the innovations and evolution of bull dog truck decks. Have a listen and gain insights on how the use of the decks has changed over the years and continues to expand. Trucks Decks are not just for Sledding any more....

In this episode of Trailer Talk we talk with Brett McDowell who shares with us the innovations and evolution of bull dog truck decks. Have a listen and gain insights on how the use of the decks has changed over the years and continues to expand. Trucks Decks are not just for Sledding any more....

Posted by Steve Whittington on Apr 22, 2014 in Podcasts

Tagged Podcast, Truck Decks, Bull Dog Decks, Super Decks, Flaman, Flaman Trailers, Brett McDowell, Steve Whittington

The 8th Annual Frank Flaman Foundation Gala: A Night of Glitz, Glamor and the Flaman Man!

I really did enjoy myself that evening. I even managed to drag my boyfriend out on the dance floor for a couple of songs. The energy in the room was lively and happy. Flaman Man himself even made an appearance and I got the chance to get my picture taken with him! Dream come true as a Flaman employee! The Gala was once again a fantastic success! I am looking forward to attending next year’s. ...

Posted by Flaman on Mar 31, 2014 in Local News

Tagged Gala, Frank Flaman Foundation, Generosity, Flaman Man

Corn Pro Trailers Podcast

Brian Frette from Corn Pro Trailers talks us through the manufacturing of the product and shares his views on the versatility of their products. (For instance snow machines in a stock trailer?) Have a listen to some great information about this respected brand....

Brian Frette from Corn Pro Trailers talks us through the manufacturing of the product and shares his views on the versatility of their products. (For instance snow machines in a stock trailer?) Have a listen to some great information about this respected brand....

Posted by Steve Whittington on Mar 10, 2014 in Podcasts

Tagged Flaman, Brian, Frette, Steve Whittington, Trailers, Trailer Talk, Stock Trailers, Horse Trailers, Podcast

Keeping Things Fresh at the Frank Flaman Foundation

Posted by Crystal Flaman on Mar 10, 2014 in Local News

Tagged Flaman Foundation, Gala, Humanitarian Trip, Website

Flaman Serves Up Some Hot Lunch

The Frank Flaman Foundation contributes funds to this and many other charities locally, and around the world. As an employee, it’s great to see the change that our donations can make within the community. I got to sit and eat with the grade one students and the smiles on their faces put things into perspective for me. It makes me proud to work for a company that contributes to worthwhile causes. ...

Posted by Flaman on Jan 15, 2014 in Local News

Tagged Community, Frank Flaman Foundation, School, Hot Lunch, Volunteer

Rain, Rain Go Away

Well, we've had about as much rain as a person needs for the rest of the year. It seems like it's been raining across the province non-stop for the last two weeks of June. We've seen an exceptional amount of flooding this year across western Canada, mainly in High River & Calgary Alberta, but the immense rain stretched and blanketed over Saskatchewan for almost the whole of the last two weeks of the month. In Manitoba and Saskatchewan, most farmers are at least a couple of weeks behind due to the late thaw of the snow, but as it happened, the thaw occurred too fast and now we're left with all this water....

Posted by Mark Flaman on Jul 2, 2013 in Local News

Tagged Rain, Flood, Flooding, Saskatchewan, Flaman, Alberta, Calgary, High River, News

Flaman Rentals introduces new Damage Waiver Fee

As of May 1, 2013, all Flaman Rentals stores and agriculture rental dealers across the prairies will be introducing a new damage waiver fee for all of our equipment rental customers. This new fee is designed to help our customers offset the high cost of equipment repairs if they accidentally damage any rental equipment while in their possession....

Posted by Flaman on Apr 19, 2013 in Product Information

Tagged Flaman Rentals, Rental, Renting Equipment, Trailers, Damage Waiver Fee, Protection

Trailer Division Meeting at Wells Cargo a success

On Thursday February 7 the Flaman Trailers division team toured the Wells Cargo plant in Ogden, Utah. We toured all areas of the more than 100,000 square foot facility. The team was impressed by the quality control processes at every step and the craftsmanship apparent in the build process. ...

Posted by Steve Whittington on Feb 15, 2013 in Product Information

Tagged Trailers, Flaman Trailer, Trailer Meeting, Wells Cargo, Trailer Manufacturers

Exciting experiences at rental dealer meeting in Cuba

Cuba… oh boy where do I start? It was a fun filled week mixed with both business and a little pleasure. I was rather excited about this trip, as this was my first full dealer get together. I was rather nervous and not sure what to expect, especially with 100 of us crazy Canadians down in Cuba. ...

Posted by Flaman on Jan 9, 2013 in Division News

Tagged Flaman Rentals, Rental Dealers, Rental Meeting, Awards

We're proud to be an ABEX finalist!

As a project manager for Flaman’s marketing team, I am proud and excited to announce we’ve once again been nominated for a Marketing Award. Flaman Group of Companies was named a finalist in the 2012 Achievement in Business Excellence (ABEX) Awards in the Marketing category.

...

Posted by Jennifer Thompson on Oct 4, 2012 in Division News

Tagged Award, Marketing, ABEX, Business Award, Saskatchewan, Flaman

Lessons from NATDA

Every year, Flaman Trailers travels to the North American Trailer Dealer Association (NATDA) tradeshow to learn about changes in the industry. This year the tradeshow was in St. Louis. This year, as we have every year, we learned a lot. There are new parts and new trailers coming into the industry and all manufacturers showcased new improvements to their line ups. This is a great event for the industry. Besides the product specific learning, we also walked away with three big thoughts....

Posted by Steve Whittington on Sep 10, 2012 in Division News

Tagged Trailers, Trade Show, NATDA, Flaman, Industry, Trends, New, Lessons, Learned

The secret behind cleaning grain with indent cylinder machines

The indent cylinder machine is designed primarily to separate grain by kernel length. It separates long kernels from shorter ones. The cylinder itself is a thin-walled tube with indents formed on the inside to the shape of a hemisphere. These indents are known as pockets....

Posted by Roy Ritchie on Aug 22, 2012 in Product Information

Tagged Grain Cleaning, Indent Cylinder, Grain Kernel, Flaman, Grain Sorting

Flaman Shares with the Community

As the new territory rental manager I had the chance to personally hand deliver a $10,000 donation cheque on behalf of the Frank Flaman Foundation to Ike Friesen of Morden, MB. Ike is one of Flaman’s all-time longest rental dealers, and has been part of the Flaman team for over 10 years now. He is also chairman for SHARE (Sharing Hope and Agriculture Resources of the Earth)....

Posted by Flaman on Jul 17, 2012 in Division News

Tagged Rentals, Donation, SHARE, Food Bank, Flaman Foundation, Charity

Third Time's A Charm

For the third year in a row, Flaman Rentals in Saskatoon has been named a Consumer Choice Award Winner. This division of Flaman rents out enclosed and flat deck trailers, along with agricultural equipment like discs, land rollers or mowers....

So You Want a Concession Trailer?

At Flaman trailers we have offered concession trailers for some time. With the addition of the Wells Cargo line, we can really offer quality concession trailers from a company that knows the industry requirements. We do receive requests for quotes for a concession trailer and they range from pointed requests such as “How much?” to more detailed inquiries....

Posted by Steve Whittington on Jun 25, 2012 in New Products

Tagged Concession Trailer, Ticket Trailer, Ticket Booth, Food Trailer, Flaman Trailers, Custom Trailer

New Rental flyer is out now

Flaman Rentals has just finished producing and distributing the new Rental Rate Flyer for our eastern Saskatchewan and western Manitoba rental stores. It contains details and safety information as well as rental rates on all of our most popular equipment....

Posted by Flaman on Mar 30, 2012 in Division News

Tagged Rentals, Equipment, Flaman, Rates, Flyer, Construction, Agriculture, Trailers

How to Choose Which Trailer to Buy

I have been in the trailer industry for a long time: 3 years as a marketing consultant to the industry, 6 years as General Manager of a trailer manufacturer and 4 years running retail dealerships. Despite all this experience, I still get overwhelmed by the diversity of choice offered to a customer in today’s market place. ...

Posted by Steve Whittington on Mar 19, 2012 in Trailer Tips

Tagged Trailer, Brand Name, Manufacturer, Service, Parts, Choosing A Trailer, Flaman

Giving back to the community

Are you looking for a meaningful way to give back to your community? Then mark your calendar and get your ticket for the 6th annual Frank Flaman Foundation Gala on March 30, 2012. ...

Posted by Jennifer Thompson on Mar 16, 2012 in Division News

Tagged Flaman Foundation, Gala, Charity, Edmonton, Donations, Fundraiser, Auction, Community

The Moosomin rental store is expanding!

Flaman Sales and Rentals in Moosomin is happy to announce that we have officially begun construction on our new facility here in Moosomin. As part of the original take over from Wayne’s Rental Centre back in the spring of 2011, Flaman knew that they would soon need a much larger facility to work out of as business grew and expanded. ...

Posted by Flaman on Jan 19, 2012 in Local News

Flaman Rentals wins Consumer Choice Award

For the second year in a row, Flaman Rentals has received the Consumer Choice Award for the best Equipment Rental dealer in Saskatoon.

Steve Whittington, an executive at Flaman, accepts the Consumers Choice Award for Flaman Rentals in Saskatoon....

Posted by Jennifer Thompson on Jun 28, 2011 in Division News

Tagged Rentals, Consumer Choice Award, Trailers, Equipment, Flaman, Award, Customers, Saskatoon

Spring Clearance and Used Trailer Sale

Every two years we replace the rental trailers in our fleets across all of our stores. We combine our pre-existing used inventory with our ‘birthday’ (clearance) trailers and add the trailers that come out of our rental fleets to make the largest trailer sale in our organization. We are currently clearing out over 350 trailers across western Canada, and we are sure we’ve got one to fit your bill. From small shuttle trailers, to motorcycle trailers, to car haulers, to dump trailers, to goosenecks, you’ll be hard pressed to find something we don’t have in our used inventory. Everything from aluminum to steel, light-duty to heavy-duty, in all sorts of colors, shapes and sizes. All trailers go through our service centers for a full inspection before they are put into our used inventory. ...

Posted by Mark Flaman on May 2, 2011 in Division News

Tagged Trailer Sale, Spring, Clearance, Used, Flaman, Rentals, Low Cost, Pre-owned