Three Phase Electricity for Grain Handling

Three-Phrase Grain Handling Power. Doable. Valuable.

More acres seeded might mean more bushels brought into your bin yard. But it doesn't have to mean more work and expense. As farming grows, new technologies emerge to boost your grain operation's speed and efficiency.

Technology Boosts Productivity.

Grain Dryers like our AGI NECO and Oakland models are designed to run continuously and safely. There's no need for you to spend your time or hire a hand to supervise them. And with remote monitoring systems, you can spend more time working in the field.

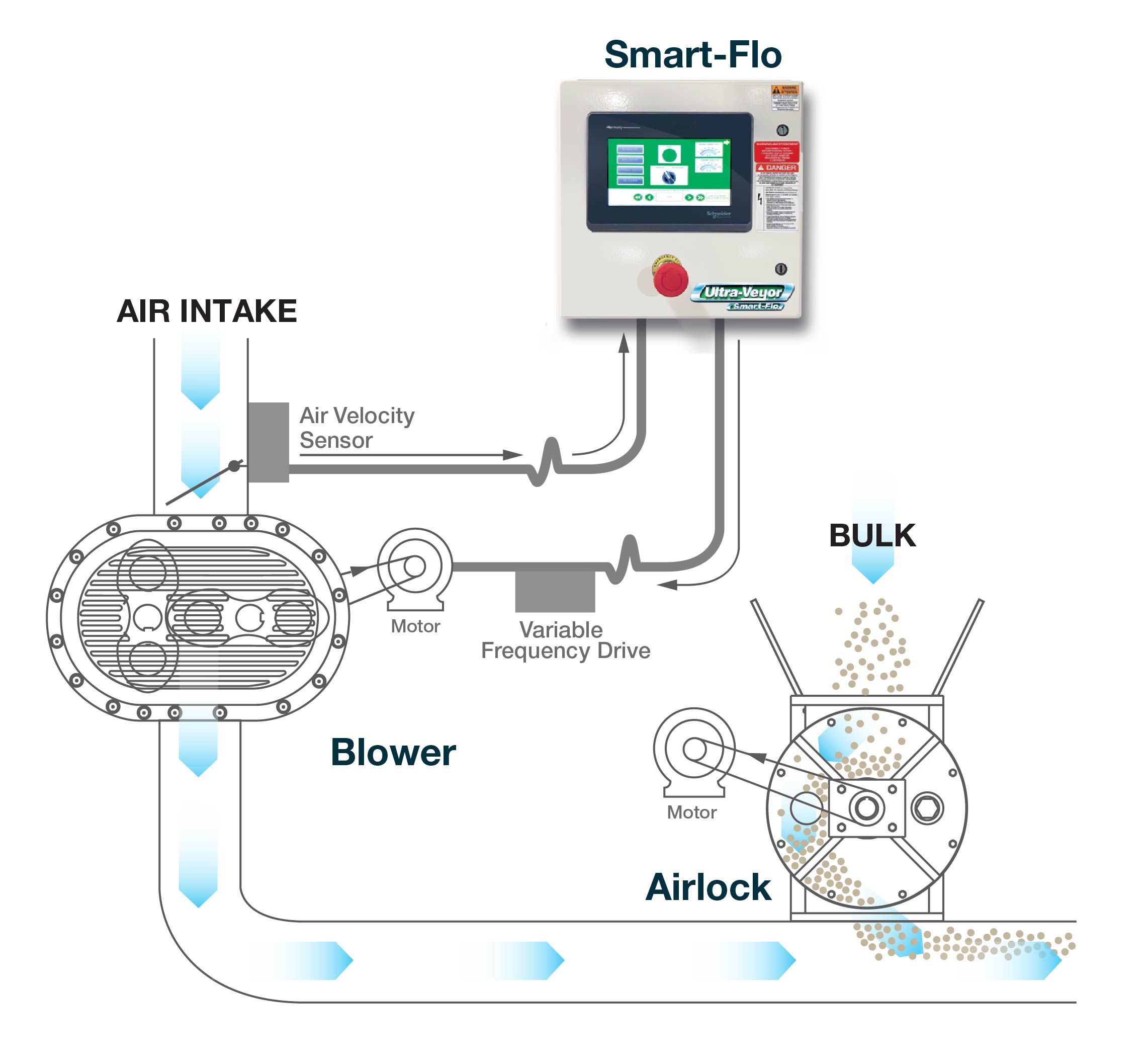

The same goes for the Walinga Blower System. Its airflow can move dried grain to your dry bins at rates of up to 2,000 bushels an hour. Achieving those higher volumes depends on the size of your piping and your motor's horsepower. The latter can be a sticking point for many farmers.

Amping Up Your Operation

Most farming operations are still wired for single-phase power. The high-volume systems mentioned above require three-phase power, which hits its peak amplitude three times as often as single-phase for three times the power output. It’s the optimum circuit for power generation. Higher-phase systems prove too complicated and expensive to be worth pursuing.

Despite its benefits, Farmers aren't often eager to rewire their farms to facilitate three-phase. Fortunately, they don't have to.

How to Convert from Single to Three-Phase Power Safely and Affordably

Walinga Blower Systems and AGI NECO and Oakland grain dryers all employ VFD technology. Variable Feed Drives have two outstanding features. First, they allow your motor to slow down and speed up, limiting energy consumption to reduce your power bill.

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

More importantly, they can be set up to draw current from your existing single-phase power source and convert it to three-phase electricity. So, you don't have to change your farm's entire power supply to run one or two bigger machines.

It's worth noting that not every variable frequency drive motor can deliver these results, but AGI, Oakland, and Walinga have engineered their motors with the farmer's single-phase/three-phase dilemma in mind.

Savings and Convenience to Help You Get Growing

There’s a big benefit to this small-scale phase shift. It removes a giant obstacle to building up your bin yard. Instead of waiting until you’ve saved up for a big change, you can increase your grain handling capacity in stages. More high-quality grain in your bin allows you to purchase more components down the road.

Ready to Lower Grain Handling Electricity Costs and Boost Production?

Get in touch with your local Flaman dealer and ask our bin yard experts how you can convert single-phase to three-phase power, add valuable components, and get your bin yard humming....

Posted by Jeff Brown on Nov 6, 2023 in Product Information

Tagged Grain Handling, Three Phase Power, Walinga, Neco, Oakland

Five Reasons to Upgrade Your Grain Handling

Wish managing your bin yard was a little less complicated? A tied-in grain-handling system can make that happen. Flaman offers several innovative components that can eliminate the effort, expense, and inconvenience of getting your grain safely in your bins. Bringing them together in one place yields a bumper crop of benefits.

1. Reduce Manpower and Save on Labour Costs

Consider all the moving parts involved in traditional grain handling – augers, tractors, and semis to drive in and unload, plus the manpower to keep them moving. Setting up a grain handling system can save you the time it takes to move and operate equipment plus the expense of hiring help.

Options like belly dumping or side dumping grain into a pit that feeds a bucket elevator can be done by one person – saving you a lot of hiring, hollering, and hand signals.

2. Minimize Maintenance Costs

You’re probably all too aware of the cost of running a tractor back and forth to your grain bins. In addition to fuel, extra operating time will also mean more wear and maintenance. Your auger flighting can also wear out, suffering more metal-on-metal damage as time goes by.

A self-propelled, belt-driven bucket elevator is designed to avoid impact points, and a pit system can eliminate the need for a tractor to move or power anything.

copy.jpg)

3. Eliminate Seed and Grain Damage

Of course, if metal can damage metal, it can easily crush any seed that gets caught between an auger’s flighting and its tube. Brittle pulses like lentils and peas are particularly vulnerable to significant and costly damage.

A gentler handling option makes good economic sense. You could employ a low-cost Hutchinson Chain Loop system, operating like a sideways-mounted bucket elevator, or you could opt for the bucket elevator itself, which carries your grain in plastic buckets for minimum damage.

Walinga’s air system takes seed and grain protection even further. Its vacuum intake and blower combo gives your crop an air-cushioned ride to the bin.

4. Invest in the Future Growth of Your Operation with a Staged Expansion Approach

Not everyone can afford to set up a state-of-the-art grain handling system on day one. Fortunately, Flaman can help you structure a budget-friendly plan to expand your grain operation whenever and however you feel comfortable.

You can build up in stages over a number of years. For instance, Stage 1 might mean setting up a reliable bin-and-auger process. Your second stage might include tying all your bins together with a grated pit and bucket elevator system. In stage 3, you might add grain storage or introduce a truck scale or an overhead unload bin you can drive your truck under. Your fourth stage might see the addition of cleaning and processing equipment.

This is just an example. You could switch it up to expand your operation as you see fit. Every customer is different, and Flaman helps each one find an individual solution.

5. Increase Efficiency

Nothing saves time and money like speed and volume. Flaman offers both. Our low-maintenance grain handling equipment is proven to provide a high degree of safety for your crop and yourself. These include grain-moving options with impressive capacities of up to 20,000 bushels an hour.

From Start to Finish, We Have It Handled

If you’d like to make life on the farm more than kinda laid-back, Flaman proudly offers the best-in-class industry experts to help you do it.

You can count on our team of certified technicians. Their collective grain-handling expertise, service, and support are yours throughout the setup, optimization, and maintenance of your operation.

Get efficient this year. Talk to Flaman about the grain handling options that can start saving you money – and about the expansion you can achieve with the money you save.

Start your better bin yard conversation by calling or visiting your nearest Flaman Agriculture Location....

Posted by Jeff Brown on Jun 20, 2023 in Product Information

Tagged Grain Handling, Walinga, Bucket Elevator, Hutchinson Grain Pump

Be ready for harvest 2022: Summer is the time to build your bins & install your grain handling equipment

Now that seeding is complete and the crops are growing, you may be starting to think about the next steps in your farming operation for 2022. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long....

Posted by Calla Simpson on Jun 24, 2022 in Ag news

Tagged Grain Systems, Grain Handling, Grain Drying, Grain Cleaning, Turnkey, Bin Site, NECO, Walinga

Grain Cart Unloading Done Just Right

It really does matter how you look at it. Watching those harvest bushels pour out of your auger may do your heart good, but your back and neck don’t fare so well.

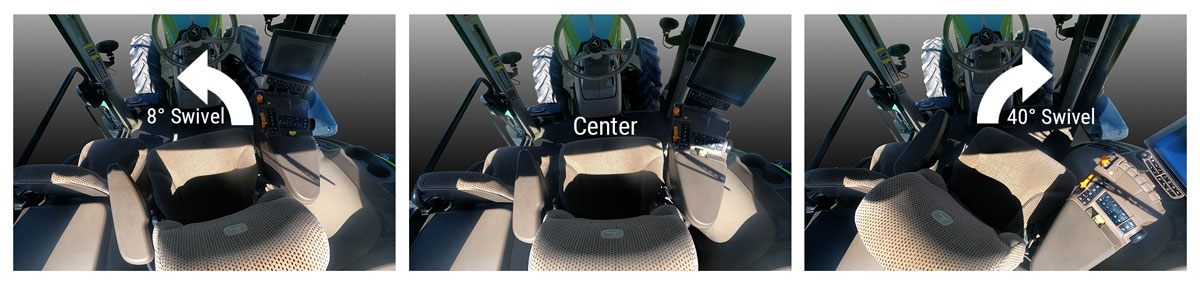

That’s because traditional grain carts unload on the left-hand side, causing you to turn away from your tractor controls. Meanwhile, anyone in your buddy seat has to do his own contortions to stay out of your way while you try to accurately offload grain. All that straining and stretching to see what’s happening makes for a long, unpleasant day - and a sore, sleepless night.

Thankfully, one simple common-sense improvement gives you a clear view of your auger without the aches and pains.

Right-side augers change everything!

J&M Manufacturing’s right-side auger grain cart makes the most of your tractor’s cab layout. Easy access to controls and unobstructed visibility allow you to effortlessly aim your auger right into the semi-trailers. The increased comfort makes grain handling more operator-friendly— with fewer visits to the chiropractor.

It works with the extended right-hand swivel of most tractor seats and provides a consistently clear view of your controls and monitors. No more groping around, hitting the wrong button, and spilling your valuable grain.

Farmer Approved

Operators have noted the left-to-right change left them less fatigued at the end of the day. ...

Posted by Jeff Brown on Jun 16, 2022 in New Products

Tagged J&M, Grain Carts, Right Side Auger, X-tended Reach, Grain Handling, Harvest

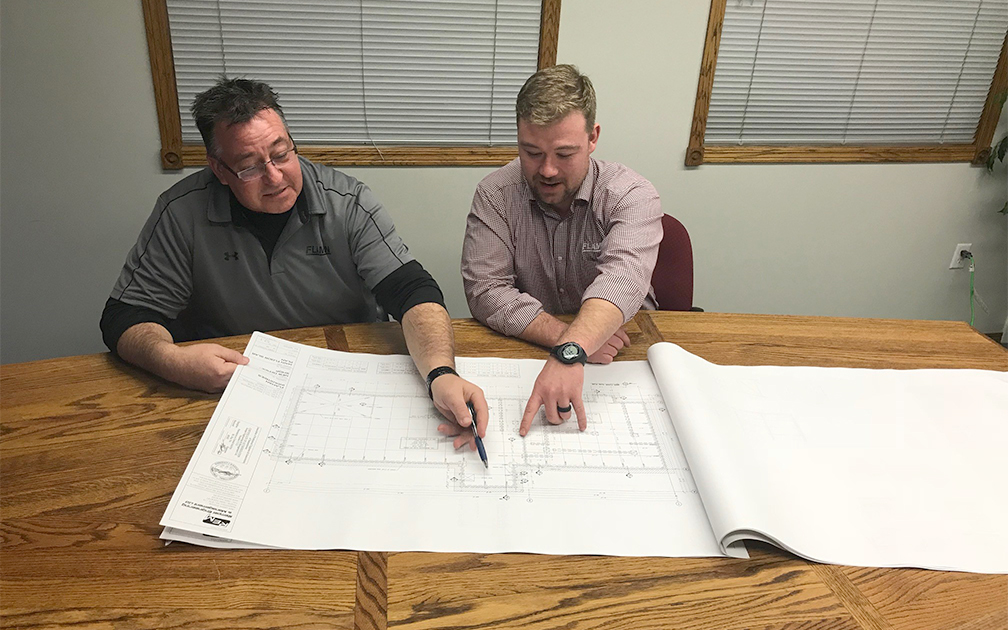

From start to finish, the Flaman Grain Systems team is right beside you

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish. ...

Posted by Mitch Flaman on Apr 7, 2021 in Division News

Tagged Grain Systems, Grain Handling, Grain Drying, Grain Cleaning, Optimization, Site Drawings, Yard Planning

From start to finish, the Flaman Grain Systems team is right beside you

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish. ...

Posted by Mitch Flaman on Apr 7, 2021 in Division News

Tagged Grain Systems, Grain Handling, Grain Drying, Grain Cleaning, Optimization, Site Drawings, Yard Planning

Three reasons the Batco BCX3 needs to be your next conveyor

It’s here. The legendary orange “gentle giant” from AGI/Batco has received more than a facelift for 2021. After a complete redesign from hopper to downspout, the BCX3 conveyor has a few new features worth bragging about. Aside from the redesigned S-Drive, new Turbo-Clean Wash System, and remodeled fuel tank, there are still 3 big upgrades that make this the most versatile conveyor yet.

...

...

Posted by Mitch Flaman on Jan 21, 2021 in New Products

Tagged Conveyor, Batco, BCX3, Grain Handling

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

Low Power Requirements:

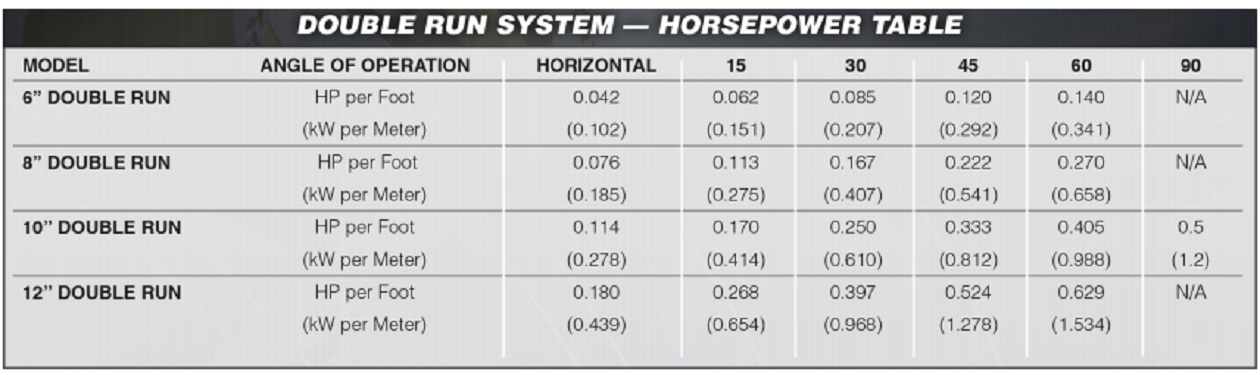

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted by Paul Boechler on Sep 14, 2020 in New Products

Tagged AGI, Hutchinson, Double Run, Chain Conveyor, Grain Handling, Grain Systems, Flaman

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site....

Posted by Calla Simpson on Aug 31, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Walinga, Ultra-Veyor, Blower System, NECO, Grain Dryer

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site....

Posted by Calla Simpson on Aug 31, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Walinga, Ultra-Veyor, Blower System, NECO, Grain Dryer

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying....

Posted by Calla Simpson on Aug 26, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Grain Drying, NECO, Grain Dryer, Mixed Flow, Continuous Flow

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying....

Posted by Calla Simpson on Aug 26, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Grain Drying, NECO, Grain Dryer, Mixed Flow, Continuous Flow

Dry your grain with ease: Get ahead of harvest this year and book your NECO dryer install with Flaman today

NECO Mixed Flow Grain Dryers are designed to easily and efficiently condition all types of grain for storage. With no screens to clean or unplug, this industry-leading grain dryer is designed not only for its performance, but also its versatility.

The flexible, modular design of these grain dryers make for easy installation and can be customized and expanded to suit any farming operation.

A time lapse of a NECO Grain Dryer installation near Saskatoon

The NECO Grain Dryer’s mixed flow operation ensures even heating and cooling to provide consistent, high-quality grain. The improved air flow, quieter fans, and unequalled fuel efficiency make this dryer a valuable addition to any farming operation.

NECO dryers use Commander Control with a Dryer Master moisture control system to protect the quality of your grain and prevent over- or under-drying. The COMMANDnet system allows remote access to your NECO Grain Dryer to monitor its performance from your smartphone or computer – providing you with total control over your dryer wherever you may be.

It is never too early to start planning for harvest, as we never know what mother nature has in store for us. Bookings are filling up fast, but there are still a few spots left to get your name on a dryer for fall. Our Grain Systems team can customize a complete grain drying system to suit your needs, guiding the setup and installation, and providing service and maintenance along the way.

Hear first-hand from Flaman customers what a NECO dryer can do for your operation

Be ready to get ahead of harvest this year – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted by Calla Simpson on Jun 26, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Grain Drying, NECO, Grain Dryer

Dry your grain with ease: Get ahead of harvest this year and book your NECO dryer install with Flaman today

NECO Mixed Flow Grain Dryers are designed to easily and efficiently condition all types of grain for storage. With no screens to clean or unplug, this industry-leading grain dryer is designed not only for its performance, but also its versatility.

The flexible, modular design of these grain dryers make for easy installation and can be customized and expanded to suit any farming operation.

A time lapse of a NECO Grain Dryer installation near Saskatoon

The NECO Grain Dryer’s mixed flow operation ensures even heating and cooling to provide consistent, high-quality grain. The improved air flow, quieter fans, and unequalled fuel efficiency make this dryer a valuable addition to any farming operation.

NECO dryers use Commander Control with a Dryer Master moisture control system to protect the quality of your grain and prevent over- or under-drying. The COMMANDnet system allows remote access to your NECO Grain Dryer to monitor its performance from your smartphone or computer – providing you with total control over your dryer wherever you may be.

It is never too early to start planning for harvest, as we never know what mother nature has in store for us. Bookings are filling up fast, but there are still a few spots left to get your name on a dryer for fall. Our Grain Systems team can customize a complete grain drying system to suit your needs, guiding the setup and installation, and providing service and maintenance along the way.

Hear first-hand from Flaman customers what a NECO dryer can do for your operation

Be ready to get ahead of harvest this year – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted by Calla Simpson on Jun 26, 2020 in Product Information

Tagged Grain Systems, Grain Handling, Grain Drying, NECO, Grain Dryer

Be ready for harvest 2020: Summer is the time to build your bins & install your grain handling equipment

As seeding is coming to a close throughout the province, you may be starting to think about the next steps in your farming operation for 2020. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long....

Posted by Calla Simpson on May 29, 2020 in Ag news

Tagged Grain Systems, Grain Handling, Grain Drying, Grain Cleaning, Turnkey, Bin Site, NECO, Walinga