AGI Batco UCX3 Conveyor. U-Trough Convenience. All Commodities.

We could speak volumes about the volumes the all-commodity AGI Batco UCX3 U-Trough Belt Conveyor can process. It’s powerful, high-capacity, and fast. In ideal conditions, it can move up to 12,500 bushels (about 340 tons) of canola in a single hour.

At that rate, it’s not sheer fantasy to imagine loading a Super B in 10 minutes. Even heavier crops like wheat and peas still whistle through at about 10,000 BPH.

Fast as that ride might be, the cereals, pulses, oilseeds, or fertilizers you put through it come out hardly the worse for wear. Gentle handling is the beauty of a U-trough system – especially one with the UCX3’s problem-solving design. It focuses on eliminating points where spillage, crushing, and other damage can occur, from intake to spout.

Advanced Leakage Protection

That starts with the redesigned collapsible hopper. It’s built low, so you can be sure it will fit easily under any bin. The new, reinforced design also maximizes grain flow by minimizing potential leakage and grinding along its sides.

A double-lip sealed edge keeps your commodities tightly in place as they travel up the conveyor’s 15” Direct X belt. It’s a U-trough-ready update of the chevron pattern used in the successful AGI Batco BCX3 tube conveyor.

Sticking With What Works

The BCX3 design worked so well that many of its features have been incorporated into, or adapted to, the UCX3. These include:

Turbo clean wash system, two belt scrapers, and belt brush. Working together in one remarkably easy clean-out process, they keep your belt debris-free and oilseed-friendly.

Redesigned S-Drive. Easily adjusted with normal tools, this feature keeps your belt running straight and true without the risk of overtightening your pinch-roller bearings.

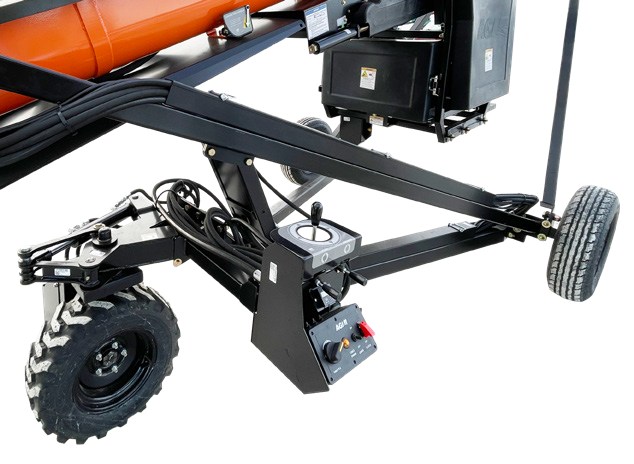

IBEX Mover Kit. Redesigned with a built-in braking system and a 160° turning radius, the IBEX is powerful and easy to maneuver whether you’re on a flat, dry surface or navigating deep muck. Two features provide the outstanding traction you’ll need to get you through a rain or snow-drenched day in your bin yard: Skid steer-style tires for better traction and single-wheel drop-and-go convenience and balance.

More Power to U.

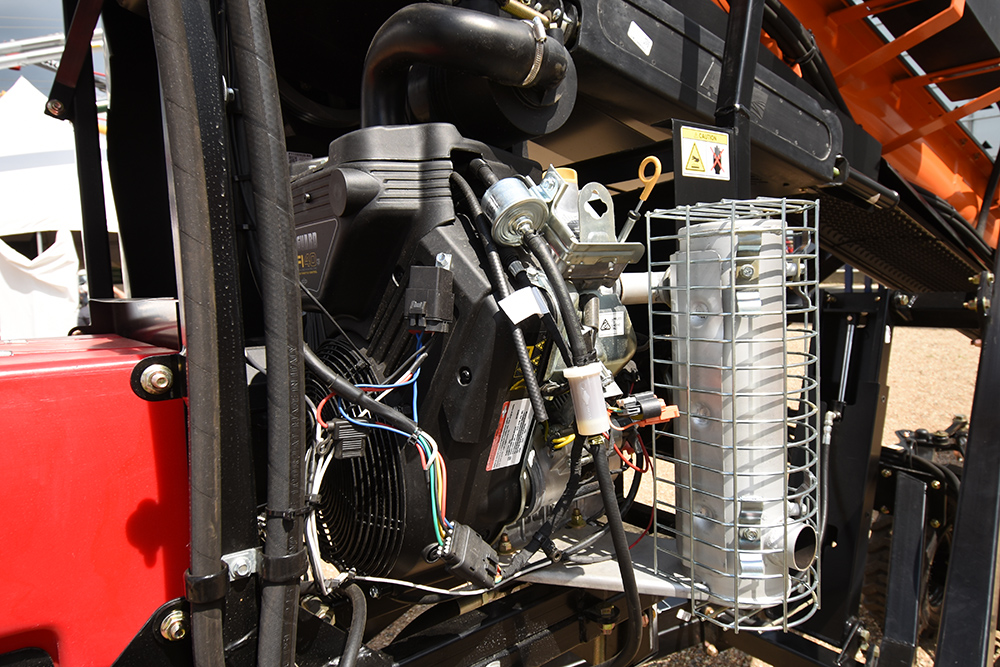

One notable difference between the U-Trough Conveyor and the BCX3 is the size of their engines. The BCX3 offers a choice of two gasoline engines – the 32HP Kohler or the 33HP EFI Vanguard. The UCX3 bumps the power up with a 40HP EFI Vanguard motor and upgraded drive components to further increase hydraulic performance and longevity.

Learn what the UCX3 can do for you at Flaman.

Want to know more about the AGI Batco UCX3 U-Trough Conveyor? You can find expert advice at 11 Flaman dealers across Manitoba, Saskatchewan, and Alberta. Drop by your nearest Flaman location and get an up-close look at features like the ergonomic command centre, IBEX Mover Kit, and spillage control.

Ask our knowledgeable sales staff how the UCX3 or any of our other equipment can help your farming operation. ...

Posted by Jeff Brown on May 8, 2023 in Product Information

Three reasons the Batco BCX3 needs to be your next conveyor

It’s here. The legendary orange “gentle giant” from AGI/Batco has received more than a facelift for 2021. After a complete redesign from hopper to downspout, the BCX3 conveyor has a few new features worth bragging about. Aside from the redesigned S-Drive, new Turbo-Clean Wash System, and remodeled fuel tank, there are still 3 big upgrades that make this the most versatile conveyor yet.

...

...

Posted by Mitch Flaman on Jan 21, 2021 in New Products

Tagged Conveyor, Batco, BCX3, Grain Handling

A Brief History of the Newest Flaman Store in Swift Current

The Flaman Swift Current and Gatco location

Products Designed by a Farmer, For Farmers

Gatco was started by a Saskatoon area farmer, Gary Schreiner. Schreiner had a problem: he was losing canola bins to overheating and needed a solution for remote bin yards that had no power. He began trying different combinations of perforated tubes in an effort to create a venting system inside the grain bin. This led to the creation of the GrainAir Tube powerless aeration system. The GrainAir tube allows heat and moisture to escape the bin quickly, by letting heat collect in the central tube and relying on convection to remove heat from the bin without any fans.

A couple year’s later, Schreiner was moving his load out auger and plastic hopper in his yard and slipped while maneuvering the plastic hopper. He knew there had to be a safer way to do this, and so the Auger Hog Hopper was born. This adjustable, detachable grain auger hopper attaches and detaches in seconds with a single mount pin, stays on your auger between bins, and adjusts from 12" to 29" in height merely by moving the handle. Due to the Auger Hog’s u-trough design, it also increases the average augers speed by 20-25% and prevents any product loss.

The Auger Hog

With the GrainAir tube working well, Schreiner felt there had to be a way to make a more efficient aeration system. While researching grain dryers, he found that air moved through grain easier horizontally, so he developed louvered wall columns that were pressurized with a common aeration fan. The air would leave the wall columns and travel horizontally to the central GrainAir tube and be released out through the bin lid quickly and easily. This CrossFlow system is far more efficient than traditional air systems, as the air travels less distance and moisture and heat is removed from the bin much faster.

“Gary came up with these unique solutions to help make farming easier,” says Bret Watson, Gatco division manager, who’s worked for the company since 2013.

Bret Watson (Gatco Division Manager & Flaman Operations Manager)

Bret Watson (Gatco Division Manager & Flaman Operations Manager)A Natural Partnership in Swift Current

It was that line of innovative, farmer-proven products that made Gatco a natural fit to join the Flaman team, says Watson, who is also the operations manager for Flaman’s Swift Current location. Gatco was purchased by Flaman Sales in 2018, when Schreiner decided he wanted to devote more time to his farming operation. “The companies are both family-owned and started on the farm,” says Watson. “We were selling to the same customers and trying to provide that same level of service. It was a nice, natural fit.”

With that purchase, Flaman Sales started their 7th store in Saskatchewan. The Swift Current location began as one-person business with Watson, but since February 2020 has added 5 more staff in sales, administration and yard staff, along with acquiring a second, 4-acre yard to expand on-hand inventory and provide better sales and service.

Mellissa Paxman (Administration), Bruce Deg (Ag Sales), Brittany Fiddler (Logistics Coordinator), and Rick Spanier (Yard & Support)

The Swift Current store is a full-service Flaman Agriculture equipment dealership, offering a wide range of in-stock grain-handling equipment such as augers, conveyors, post pounders, grain vacs, grain carts, grain bins, grain dryers, grain monitoring, and water and fertilizer tanks. Customers can also order products from the Flaman catalogue like discs, mowers, chem handlers, pumps, and more.

Bob Schafer (Ag Sales)

Bob Schafer (Ag Sales)“We’re proud to offer equipment options to the local community,” says Watson. “Farmers don’t have to drive to Saskatoon or Southey anymore. This location allows Flaman to serve customers all over southwest Saskatchewan.”

-----

Want to learn more? You can view some products in inventory or contact our Swift Current location.

Posted by Jennifer Thompson on Jul 7, 2020 in Division News

Tagged Agriculture, Swift Current, Flaman, New Store, Local, Shop Local, Southwest Saskatchewan

ATC Trailer Podcast

In this episode of Trailer Talk we learn about ATC trailers, their value stream manufacturing and some really unique products. Industry veteran (24 years!) Trent Sheets tells us the story....

In this episode of Trailer Talk we learn about ATC trailers, their value stream manufacturing and some really unique products. Industry veteran (24 years!) Trent Sheets tells us the story....

Posted by Steve Whittington on Jan 29, 2014 in Podcasts

Tagged Trailer Talk Podcast, ATC

Rain, Rain Go Away

Well, we've had about as much rain as a person needs for the rest of the year. It seems like it's been raining across the province non-stop for the last two weeks of June. We've seen an exceptional amount of flooding this year across western Canada, mainly in High River & Calgary Alberta, but the immense rain stretched and blanketed over Saskatchewan for almost the whole of the last two weeks of the month. In Manitoba and Saskatchewan, most farmers are at least a couple of weeks behind due to the late thaw of the snow, but as it happened, the thaw occurred too fast and now we're left with all this water....

Posted by Mark Flaman on Jul 2, 2013 in Local News

Tagged Rain, Flood, Flooding, Saskatchewan, Flaman, Alberta, Calgary, High River, News

We're proud to be an ABEX finalist!

As a project manager for Flaman’s marketing team, I am proud and excited to announce we’ve once again been nominated for a Marketing Award. Flaman Group of Companies was named a finalist in the 2012 Achievement in Business Excellence (ABEX) Awards in the Marketing category.

...

Posted by Jennifer Thompson on Oct 4, 2012 in Division News

Tagged Award, Marketing, ABEX, Business Award, Saskatchewan, Flaman

New website, new dealers for summer 2011

This spring has been a very different one for many producers in the prairies, from near disastrous flooding in the southern parts of Saskatchewan and Manitoba, to drought in northern Alberta and B.C. It seems that nothing is predictable in the agricultural sector anymore (if it ever was)....

Posted by Barrett Prokopie on Jul 5, 2011 in Division News

Tagged Rentals, New, Website, Dealers, Ag Equipment, Trailers, Saskatchewan, Alberta

Why Buy Aluminum

Well, there are many reason to buy an aluminum trailer vs a traditional steel trailer. Firstly Aluminum is lighter by 35- 45% which means your payload is going to be higher than a steel trailer with the same axle rating. Generally though most aluminum trailers have a lighter axles than their steel counterparts but are still able to offer the same payload. This equals a less weight to haul (better fuel economy) and your trailer is easier to move around when hitching up....

Posted by Steve Whittington on Feb 1, 2010 in Product Information

Tagged Information, Aluminum, Aluma, ATC